Hastelloy pneumatic regulating valve uses compressed gas as the power source, cylinder as the actuator, and drive the valve by means of valve positioners, converters, solenoid valves, security valves, gas filters and other accessories to achieve the switch or proportional regulating. Hastelloy pneumatic regulating valve is characterized by simple control, fast response, intrinsic safety and no need to take explosion-proof measures.

The uses and features of Hastelloy pneumatic sanitary regulating valve:

1. It uses a right-angle rotary structure. Used with valve positioner, it can achieve proportional regulating. V-shaped valve is most suitable for a variety of regulating occasions. Its rated flow coefficient is big, sealing performance is good, regulation performance is sensitive, size is small, and it can be vertically installed. It’s suitable for controlling gas, steam, liquid and other media.

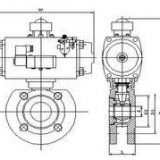

2. It consists of V-shaped valve body, pneumatic actuators, positioners and other accessories. It uses double-bearing structure, with a small starting torque. It has very good sensitivity and speed of induction and super good shearing capacity.

3. Pneumatic piston actuator uses compressed air as a power source, rotates 90 degrees with the crank arm through the movement of the piston to make the valve automatically open and close. Its components are: adjustment bolts, actuator box, crank arm, cylinder block, cylinder shaft, piston, connecting rod, universal shaft.

The mechanism of Hastelloy pneumatic regulating valve: It’s comprised of actuating components and regulating components. The actuating component is the thrusting part of regulating valve. It produces the thrust according to pressure of the control signal, making the regulating component work. The valve body is the regulating component of Hastelloy pneumatic regulating valve. It has a direct contact with regulating media to regulate the flow of the fluid.

Notes to take when using Hastelloy pneumatic regulating valves:

1. The valve should be stored in a dry room, both ends of the pathway must be blocked. No stack storage.

2. Regularly check the regulating valves in long-term storage and remove dirt. Coat with rust-proof oil on all movement parts and processing surface to prevent rust.

3. The valve should be installed in the horizontal pipeline, with vertical installation and valve stem up.

4. Install according to the flow direction of the medium.