V type pneumatic ball valve is a core seat is made of metal, rotating ball valve on the PTFE sealing, the utility model has the advantages of the best control characteristics of ball and butterfly valves are combined into a whole, can be used as an adjusting valve, and can turn off the shut-off valve. As a result of shear function, it is very suitable for the media in the case of particles.

The main features of pneumatic V type regulating ball valve:

(1) the integral valve body without any pipe joints, so it is not affected by the pipe or bolt stress, and because the body does not have any pipe joints, so the pressure casing will not be affected by the pressure “mutation”;

(2) has a V type valve body, even in the case of small flow or high viscosity media, but also in the entire range of measurement, to ensure the accuracy of control;

(3) When the valve is closed, producing wedge shear force between V notch and the valve seat, and has self-cleaning function and can prevent the ball stuck, especially suitable for freezing pipeline or containing fibers and particles of solid.

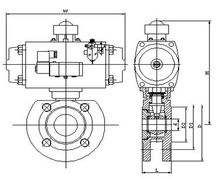

It is suitable for high viscosity, suspension, pulp and other clean, fibrous media occasions. Directly connected with the implementing agencies, with compact structure, small size, light weight, small resistance, stable and reliable action. According to the requirements of the user, the actuator is equipped with a pneumatic piston actuator. The regulating valve is used to regulate the flow, pressure and liquid level of the medium. According to the adjustment signal, automatic control valve opening, so as to achieve medium flow, pressure and liquid level adjustment.