The leakage phenomenon can easily generate an “unwanted flow rate” (or “parasite”) that generates a “parasitic thermal power” of about 5-7% of the nominal one. It follows that in a 4-pipe system (such as fancoil, VAV with post-heating or hot / cold exchangers of an AHU) to maintain the desired comfort conditions it is necessary to compensate the “parasitic thermal power” with an equal and opposite power. It is common to find that in the summer (or in the intermediate seasons) the battery of the fancoil heat is “lukewarm”; it follows that the power required by the cold battery will be greater. All this translates into a doubling of the total required thermal power (between cold and hot circuit) that can reach values of 10-15% of the nominal power of the plant. And like a car whose brakes are not completely disengaged by reducing the power to the 5% axis, in addition to the increased consumption necessary to keep the speed constant, will have a premature wear of the brakes themselves.

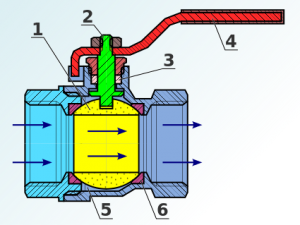

The 6-way sanitary ball valves, compared to traditional modulating valve or globe valves guarantee:

- Saving of the total thermal power of the system

- Saving of the electric power of the auxiliaries (pumps, fans, actuators …)

- Better regulation

- Space saving (replaces 8 valves)

- Savings in time of installation