As far as I know all sanitary pneumatic diaphragm valve, the body must be welded on the process before the demolition of the implementing agencies. And the installation of sanitary pneumatic diaphragm valve is not a trivial matter, do not treat him as a “child’s play.” Before the installation of sanitary pneumatic diaphragm valve, please read the operating instructions to confirm the use of the pressure valve conditions, and to provide the appropriate air (4 ~ 5.5bar) in accordance with the selected valve, to avoid the valve can not be normally opened and closed.

Installation:

1. The applicable safety regulations must be observed.

2. Pipeline before the installation of the valve to ensure that no impurities, or will cause damage to the valve.

3. Connect the sanitary pneumatic diaphragm valve, pay attention to align the pipeline.

4. All sanitary pneumatic diaphragm valves must be disassembled before the welding process on the valve body.

5. Replace the diaphragm, the diaphragm and the sealing surface need to be kept the open connection, then the diaphragm and the sealing surface separated.

How to open sanitary pneumatic diaphragm valve:

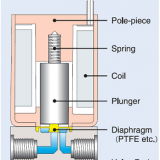

1) Vent the actuator so that the diaphragm lifts off the sealing surface.

2) cross-demolition of the body of the four screws, so that the actuator and the valve seat separation, cut off the gas source, replace the diaphragm.

3) Vent the actuator so that the diaphragm is retracted.

4) the diaphragm and the seat on the sealing surface of the good, cross-mounted set screws, repeated ventilation several times.

5) close the diaphragm valve leak test, can be used normally.

Sanitary diaphragm valve shaft packing:

① As the pneumatic valve in the pipe network, is usually opened and closed infrequently, requiring filler of inactivity in a few years , the filler is not aging, long-term to maintain the sealing effect;

② valve shaft packing should also be subject to frequent opening and closing, the good sealing effect;

③ In view of the above requirements, the valve shaft fillings do not change or not to replace for ten years ;

④ sanitary diaphragm packing can be replaced, the design of pneumatic valves should be able to consider the conditions of the replacement of water pressure measures.